by Lucy Iantosca, Sierra Circuits

The latest IPC Designers Council held at Cadence in San José, CA, was all about IPC-2581. Presented by IPC Consortium Chair Hemant Shah, the lunch meeting answered why IPC-2581 is the go-to standard. Similar to the Mentor Graphics-owned ODB++ in terms of functionality, it takes the lead over its competitor for it is open and neutral. And when it comes to good ol’ Gerber, it might just be time to retire.

IPC-2581: intelligent, open and neutral

It is easy to say that IPC-2581 is open and neutral. But how open and neutral is it really? Released in 2004, the new data and transfer methodology promised to offer a smoother CAD-to-CAM data exchange process without human intervention.

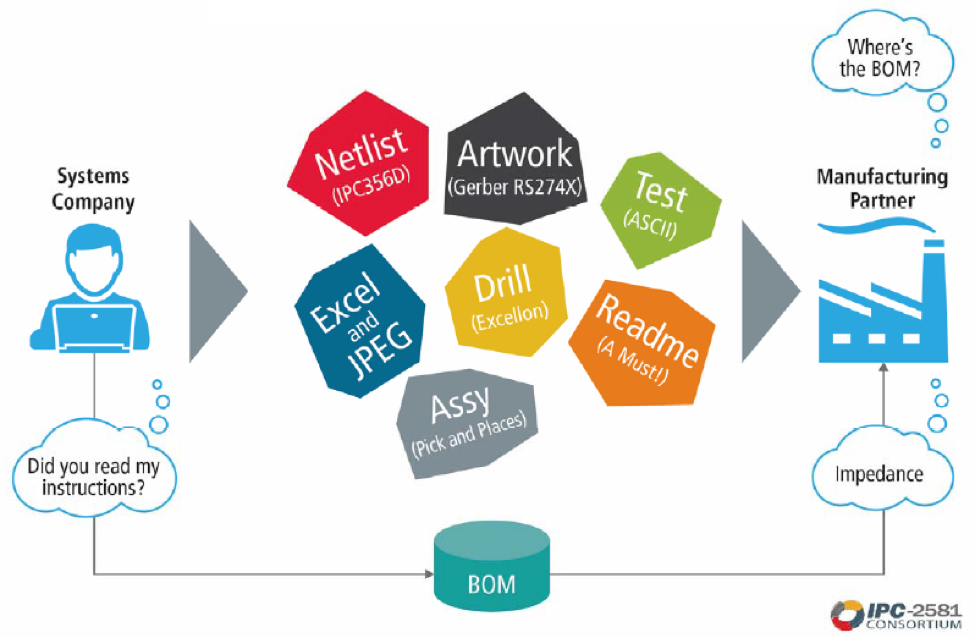

Hemant Shah began his presentation with a well-known statement: Circuit board design comes with its share of files. And we’re talking about a lot of files to deal with: Netlist (IPC-356D), Excel and JPEG, Drill (Excellon), Artwork (Gerber RS274X), Readme files of notes and instructions, and so on.

As a PCB designer, why should you care about whether your manufacturer receives your design in one or a thousand files, as long as it is sound and thorough? More files means more work and more work means more chance to make mistakes. When gathered in one single file, the design can effortlessly be imported, augmented, and exported by any business system throughout the value chain. As simple as one single file: This is the intelligent part.

At some level of circuit complexity, you might want to consider opting for a highly organized and efficient means of exchanging data with your fabricator, therefore reducing the margin of error on both sides of the hand-off.

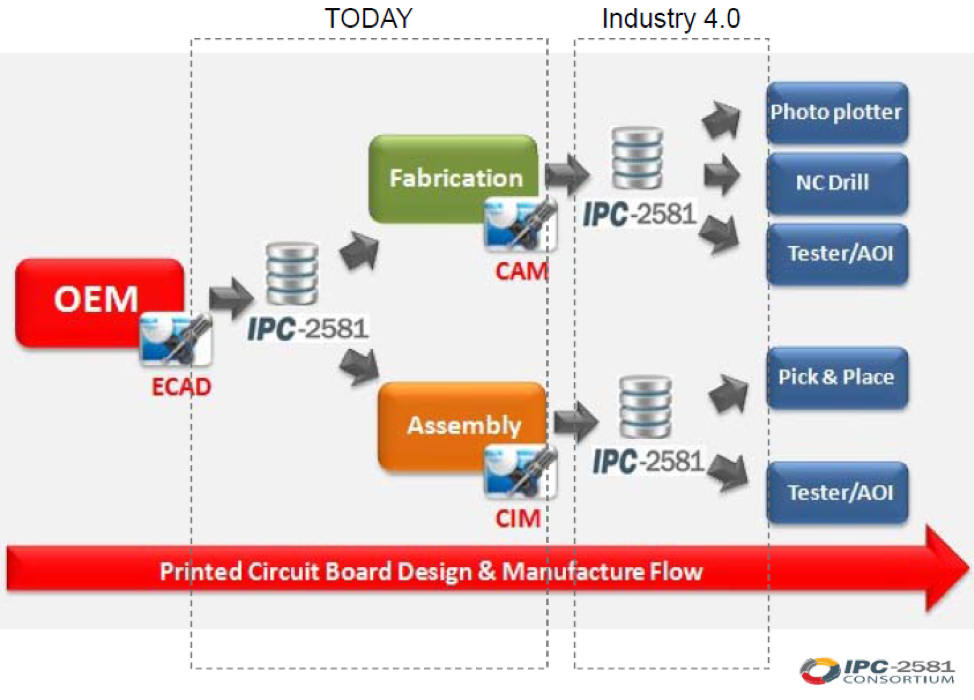

Hemant Shah carried on explaining the vision IPC had when the Consortium started working on the new standard, “The bottom line is the hand off of OEM to manufacturers. This is where we focused most of our attention so far because this is the problem that we wanted to solve. The vision was that IPC-2581 goes all the way to the machines that the manufacturers have, all the way down to the factory floor.”

IPC has a standard called CFX – which stands for Connected Factory Exchange – that passes machine specific data to different machines. That is one task designers don’t have to worry about. If you have a Pick-and-Place machine, all you need is the parts the machine needs to work on. This data for the pick-n-place machine will go to the machine in IPC-2581 format.

IPC-2581 is an IPC standard. It is not owned by anyone, everybody can implement it; thus comes the open part. It was developed in 2004 in an effort to combine the best of ODB++X – which does no longer exist – and GenCam.

Even though the format was released almost 15 years ago, the first IPC-2581 circuit board was only fabricated in September 2012. The bare board was fabricated with a PCB design from Fujitsu Network Communications, which exported the fabrication data from Allegro. The communications equipment company announced that the overall fabrication preparation time was reduced by 30 percent.

Interestingly enough, it is around that time that Mentor announced that it supported its rival standard. Currently, many other tool providers support IPC-2581: We can name Altium, Cadence, Zuken, Siemens, Polar Instruments, Adiva, Wise Software… This is a clear hint that the neutral XML based standard is a must-have.

ODB++ users will love it: IPC-2581 offers all the advantages of the Mentor format without requiring its users to get a license. It was made to serve the Industry 4.0.

Why manufacturers support IPC-2581

It makes sense that some PCB designers may still be reluctant to use IPC-2581. Just like they were when OBD++ came around and they had the choice to move on from Gerber. Truth be told, as a PCB manufacturer, we still receive 80% of our customers’ designs in Gerber. How can we convince them to use IPC-2581 when they even haven’t switched to ODB++ yet?

… Continue reading about why manufacturers support IPC-2581 on the Sierra Circuits blog