DPMX And The Digital Thread”

Michael Ford, Aegis Software

There are two aspects to a Digital Thread that are essential for modern manufacturing, both of which are related to the context in which we use data to create value. We tend to dwell on the aspect that represents daily burden to the industry with occasional benefit, whereas we should be focusing more on everyday values. Let’s get to grips with what Digital Thread is all about in manufacturing, and why design data, in the form of IPC-2581 DPMX (Digital Product Model eXchange) is an essential ingredient.

There are popular television programs that trace human genealogy back generations, to find out interesting aspects of someone’s heritage, famous or infamous antecedents, or perhaps, heaven forfend, a scandal! Specialists spend many hours navigating through historical records and documents, all of which were originally written down as isolated facts, in almost indecipherable handwriting, saved for years within paper archives, before being digitized in various databases. It is clear to anyone doing this as a hobby, that the reverse engineering of combinations of facts from disparate sources, often results in incomplete or erroneous assumptions having to be made, especially where there have been circumstances where certain events have not wanted to be widely known.

In our digital world then, we need to learn our lesson, and be careful about how we record and store data relating to the genealogy of products, their sub-assemblies and materials, such that all events and actions in manufacturing are associated and connected with the original design intent, engineering decisions, and manufacturing operations. Enterprise Resource Planning (ERP), Product Lifecycle Management (PLM) and Manufacturing Execution System (MES) tools, are there to manage and control exactly how, where and when products are being made. The Digital Thread is the historical build-record of that which was actually done, based on those plans and instructions, including measurements and assertions associated with each of the different process steps that the product and its component parts went through. This data, in isolation, is normally referred to as traceability. It is the context of the traceability data, taken together with the original design, manufacturing and materials choices and decisions, that constitutes the Digital Thread.

The first aspect of the use of the digital thread, is to use it as evidence of responsibility plus determination of scope, should anything go wrong in manufacturing in terms of quality or risk. As exceptional events are never planned nor intended, the associated benefits, while very significant, are not often considered as tangible. The costs associated with data collection and processing on a daily basis, however, are very tangible, resulting in decisions to minimization of investment, where only this one aspect is considered.

The second aspect is the use of the Digital Thread to create daily benefits, as a central part of a very effective quality management tool. The specific circumstances that lead to even the most difficult of one-off defects, can be determined, tracing the unique root cause back to the source and circumstance, enabling effective and automated CAPA / FRACAS processes to be put into place that avoid the repetition of such conditions. This is in contrast to most quality management solutions today that generalize symptoms and scope of defects, obscuring the true root causes, making any corrective actions wasteful in most cases.

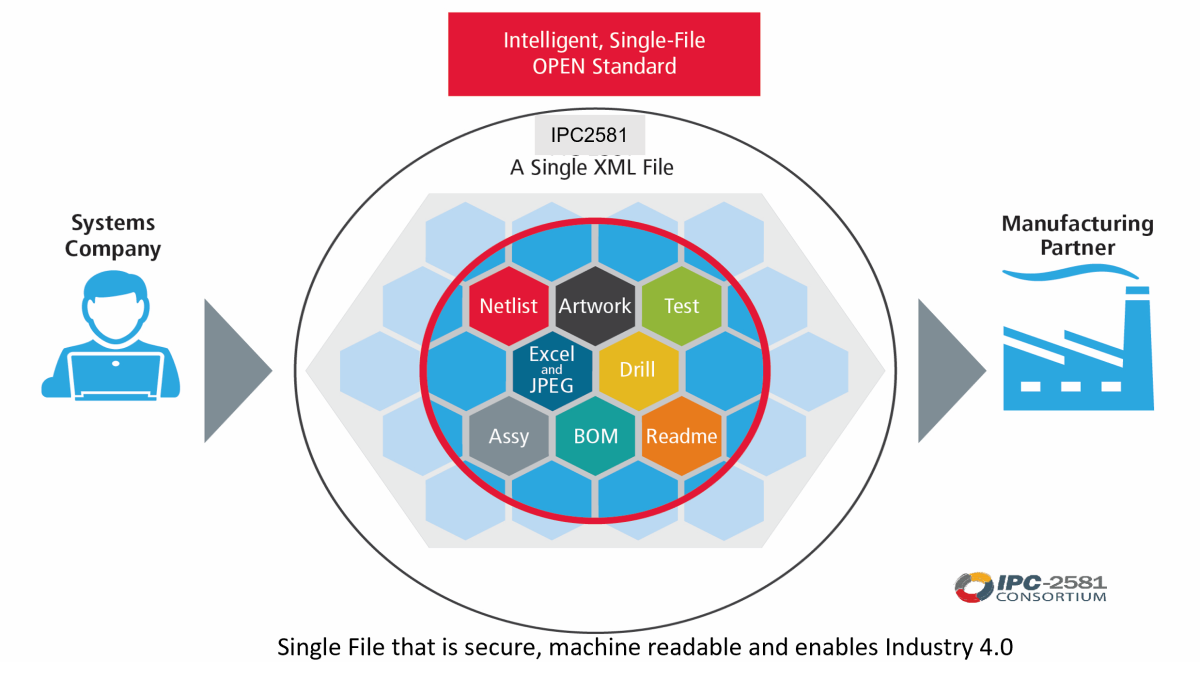

In the case of PCB manufacture and assembly, digital best practices in manufacturing start with the design data, requiring a holistically clear, detailed, and consistent set of data that describes the design intent, without the risk of manual data manipulation errors, inconsistencies or required corrections. IPC-2581 DPMX is the obvious and essential choice as compared to other methods that require reverse engineering of data between different documents and files, as the standard provides a single file representation of the complete design data. The file is suitable for direct and immediate use in Digital Manufacturing Engineering tools, that assign assembly, inspection, and test work across automated and manual configurations, as well as being used as a reference directly on the shop-floor at production stations.

Building your tree of knowledge, your Digital Thread, contextualized based on clear design information with IPC-2581 DPMX, should be one of the most important steps that you can take to ensure success in your Digital Transformation of manufacturing practices.

Follow us on LinkedIn – https://www.linkedin.com/company/67154623/ – to stay up to date on the benefits, adoption and progress of IPC-2581 DPMX.

Join us as an associate member or as a corporate member to leverage the experience of over 100 companies and scores of associate members and to influence the direction of the standard – Join – Corporate Membership | IPC- 2581 Consortium (ipc2581.com)

Join – Associate Membership | IPC- 2581 Consortium (ipc2581.com)